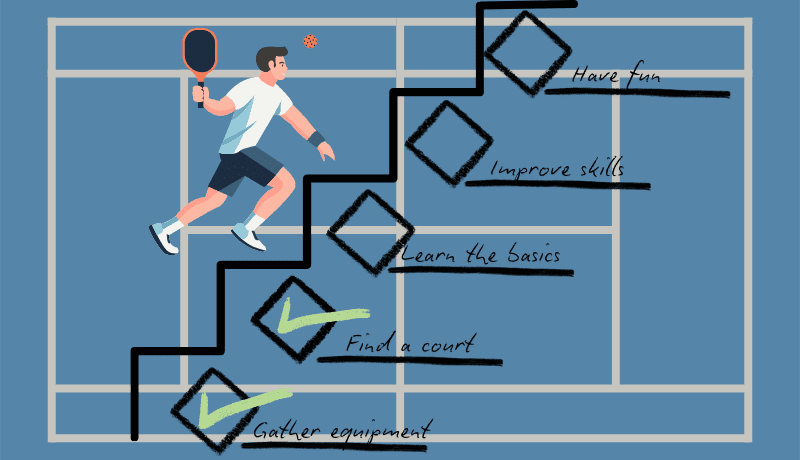

The checklist is just the beginning, part 1

Checklist is a first instrument to work with the complexity of life but it is far from being the last one. This article depicts the transformation of the checklist into the physical instrument.

In the article “How to create a working checklist?” it was mentioned that a checklist is the first way to respect the complexity of life. If there is a first, then there is a subsequent one. Let's look at how to embed a checklist into an item. We’ll use a toolbox as an example.

Let's assume that we have the following tools:

- A hammer with a separate rubber casing.

- Adjustable spanner.

- Bits screwdriver with 12 bits.

- Combination pliers.

Let it also be present a shallow box where these tools are stacked. Just like the one in the illustration.

We are fascinated by the work, and therefore it is convenient not to search for the right tool every time, but to know exactly where it is. Therefore, we put the tools from left to right in the following order:

- Pliers.

- Screwdriver with bits.

- Hammer with rubber casing.

- Adjustable spanner.

Everything seems fine, the order is set, but here's the problem. Other people sometimes take our box. They don't know how everything is arranged in it, and they stack the tools haphazardly. But we are not afraid of difficulties. We'll take a small piece of paper and write a tiny checklist on it.

From left to right:

• Pliers

• Screwdriver with bits

• Hammer with rubber casing

• Adjustable spanner

We will stick the sheet on the transparent lid of the box with scotch tape. This way it will immediately become clear what to do, where is left and where there is right.

Let's make a few more assumptions:

- The users of our box are polite and responsive people.

- Users can read.

In such pleasant conditions, peace and order will come to our box.

Okay, they will almost come. Occasionally, we need to take the box somewhere, and everything in it gets mixed up. Plus, the lid is often open, and the checklist is facing down, so new users of the open box do not return the desired order. What should we do? We need to embed the checklist in the box.

Look at this popular set of tools. Is there a high probability that the pliers will be in place of the adjustable spanner? It is small, the very structure of the box doesn’t allow this switching to happen. You can put the screwdriver in place of the hammer, but the whole set will still not compile after that.

What else do we gain after such a transformation? Now it’s no need to waste time on training, and you don't even have to read the checklist! There was a hitch in reassessing the order: “Wouldn't it be better if I put everything differently?” Now it’s gone. This is also a small disadvantage — we have complicated the further rethinking of our box and its improvement. However, who knows if it can be rethought in any significantly better way?

The mentioned acceleration of learning and removal of rethinking hitch may not look serious yet. This is a result of our primitive example, but there are examples that are much more complex. For example, in lean manufacturing, there is a method for dealing with defects “Poka-yoke”, which means “error prevention” [1]. It is about the creation of the environment and tools in such a way that the probability of defects is either excluded or seriously minimized. That is, people do not need to remember a long list of rules because it is already reflected in the way production is organized. In this case, embedding the checklist in the environment scales to the entire production and serves as a mean of significant costs reduction.

In the next part of this blog post series, automation of the checklist will be discussed.

List of links:

[1] “Poka-yoke” from Wikipedia