Station Observation Checklist Outside McDonald’s

Getting acquainted with station observation checklist in organizations outside McDonald’s. Post written together with former Standards Director of a 1100+ restaurant chain.

Contents

This post is quite extensive. The table of contents will help you navigate through it.

- Why Do We Trust Restaurant Chains?

- Today's Guest on the Blog: Alexander Kasyanov

- A Very Short History of Observation Checklist (SOC)

- Purpose of SOC

- Five Types of SOC at “Dodo Pizza”

- Example of a Checklist Applied

- Observing Employees in a Restaurant Using SOC

- Conclusion

- List of Links

Why Do We Trust Restaurant Chains?

When you visit an unfamiliar city for a business trip, at some point, the question arises: “Where to have lunch?” You are here not for adventures. You visit this place for maybe just a day. You try to identify something predictable and affordable. Would you choose a local café or a chain restaurant?

Maybe in a local café they might treat you as a valuable guest and try to do the best commitment. However, you will more likely take a lower risk and lead to a chain restaurant. Why? Because of its predictability.

Where does the knowledge of the predictability of a chain restaurant come from? It is surprising that you can go to another city or even another country, find a familiar sign, expect to feel comfortable there, and try out the food there.

You can roughly imagine how you will be greeted and how your order will be taken. For example, at a McDonald’s restaurant, you can expect a consistent experience due to their strict standards and regulatory compliance.

How is this synchronization of actions and results of completely unfamiliar employees achieved? There is no magic involved, but the essential tool is standards.

Today's Guest on the Blog: Alexander Kasyanov

Today, the “So List” blog features a wonderful guest, former Standards Director of the “Dodo Pizza” chain, Alexander Kasyanov. Alexander runs the Telegram channel “Revolution in Standards | Alexander Kasyanov” (in Russian).

In it, he elaborates on his experience in setting up processes in various enterprises in both Russia and abroad. Alexander writes about employees' performance, organizations' standards improvement, productivity observations and other standards-related insights.

So, this post is not about training McDonald’s employees, but about the training process of the “Dodo Pizza” workers. Which is a great demonstration of SOC applicability outside McDonald’s.

Today, the blog is also introducing a new section: “So Business List.” This section is about how different companies use lists and checklists to improve their employees' skills, establish consistent working practice, create the environment of quality and continuous improvement.

Even well-written standards will not execute themselves. For example, states have legislative and executive branches. The first issues laws, and the second ensures their execution. The same applies to enterprises.

It is not enough to issue a standard; you also need to ensure its implementation. How can this be done? There are too many ways, but we don't need them all. Let's consider just one of them — the observation checklist (OC) and the control process built around it.

A Very Short History of Station Observation Checklist (SOC)

Lists or checklists are unremarkable phenomena, as is their history. This blog has already attempted to discover the approximate years of the emergence of lists. The history of checklists was also explored here. Each time, the first mention sounds as if it is something everyone understands.

One might hope that the case with observation checklist would be different. After all, it looks like an essential tool of scientific management. This means that it must have appeared in the past 130 years. About that long ago, Frederick Taylor began his research on scientific labor organization [1].

Unfortunately, no. The first mentions of the observation checklist were found to be self-evident in 1944 in the journal Sociometry [2].

You might have noticed that I use OC here, and not SOC. What is the reason for this? Observation checklist (OC) is the name outside McDonald’s. And SOC stands for station observation checklist. McDonald’s resources don’t tell, what “station” is, so it is a bit mystery for me. I asked on Quora about its origins, but don’t know the answer yet. Write in the comments if you know why it is needed.

According to Alexander, modern observation checklists possibly originated in McDonald’s. Indeed, I could find that they existed and were used in this corporation as early as in 1976 [3].

Training program for employees of McDonald’s using SOC continues in our days as well. There is not that much information available online, but you can find the McDonald's SOC PDF from 2012 on web.

Purpose of SOC

Why does a company need observation checklist? At “Dodo Pizza,” they answer this question as follows:

To help managers at all levels improve the efficiency of the pizzeria.

Observation checklists also allow the following:

- Evaluate the company's performance based on standards and established processes;

- Confirm service quality and avoid security incidents;

- Prepare feedback for the team;

- Plan follow-up;

- Identify areas for growth and highlight priorities for further development.

Five Types of Observation Checklists at “Dodo Pizza”

At “Dodo Pizza,” there are five types of observation checklists:

- SOC for the territory manager. The territory manager is responsible for several pizzerias. The regional manager fills out his observation checklist.

- SOC for the restaurant manager. Filled out by the territory manager.

- SOC for the shift manager. Used by the restaurant manager.

- SOC for kitchen staff, cashiers, and couriers. Filled out by the shift manager.

- SOC for shift handover. Assesses the activities of shift managers during shift handover. Conducted by the restaurant manager.

We've understood the purpose and types of observation checklists. How do we work with them?

Example of a Checklist Applied

The “So List” blog wouldn't be itself if it didn't regularly conduct thought experiments. Let's imagine we are dealing with the very foundation of a pizzeria — pizza dough. That is, we are now the employees, the dough makers. Let's put on aprons. The hall is already full of guests.

We already had our operator training classes conducted by our manager. He and our experienced colleagues are the local training professionals. We have to be careful as we are in the real kitchen, and there are rules for safety. However, hardly it’s possible to find the more productive training environment than this one.

We have our checklist for observations. There's also a shift manager who fills it out. The cashier has accepted the guest's order. This guest will have to track their order on the screen. We look at the dough; the manager looks at us. The eyes of all participants are full of skill and passion. This is not the training process already, it’s a real work.

Let's see what points our observation checklist contains. It is divided into several categories and, in some aspects, overlaps with the SOCs of other kitchen employees. So, the list:

- Management:

- Adheres to work priorities;

- Knows and performs tasks at their position;

- Follows the manager's instructions;

- Works according to their assigned checklist;

- Observes production safety standards to avoid accidents.

- Customer Experience:

- Service:

- Neat appearance according to the standard.

- Cleanliness:

- Correctly uses cleaning equipment;

- Maintains order in the workplace;

- Performs regular checks and keeps the workshop clean.

- Quality:

- Complies with dough preparation standards;

- Follows the FEFO principle *;

- All labels meet the standard.

- Service:

- Team:

- Behavior is polite in communication with the team;

- Submits to discipline.

Can the presence and use of this list make us the best dough makers, even despite our best commitment? No, it, although containing 15 specific points, is still very vague. This will be especially noticeable to those who have read the post about operational definitions.

What does this mean? This means that the observation checklist is just the tip of the iceberg. It outlines the top of a mass of standards, processes, and training within the brain-friendly study method as well as employee engagement. All this is not included in the document but undergoes its regular observations.

Observing Employees in a Restaurant Using SOC

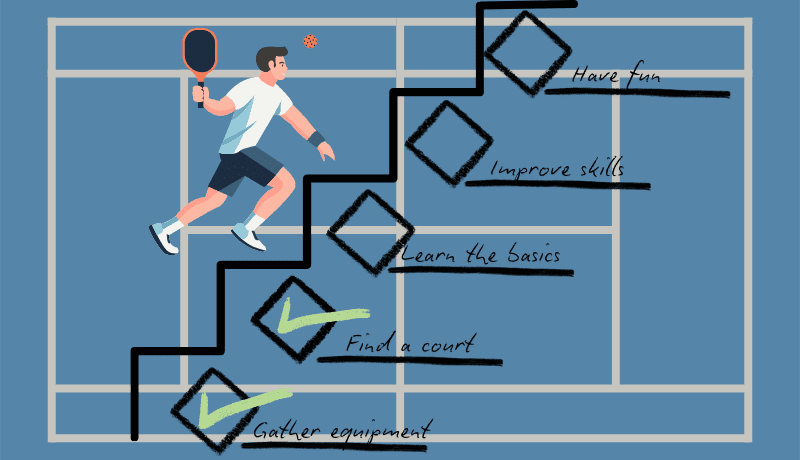

The observation checklist is used in three stages:

- Observation,

- Feedback,

- Follow-up.

Let's imagine now that we are not a kitchen employee, not a dough maker, but a shift manager. Let's consider each of the stages in more details. We now look at the employee performance. Also, let's not forget that the pizza dough is still being prepared while the guest is waiting.

Observation

A lot happens in a fast-food restaurant. High traffic requires serious control. Without high traffic, there won’t be enough sales to sustain the pizzeria itself. This is one of the main requirements for restaurant premises in the “Dodo Pizza” chain.

The manager has a significant job to do and a checklist to comply with. It has many more items than the dough maker’s one. There are 20 categories, each with several points. It also takes significant time to observe the actions of kitchen workers. Now, we are observing the dough maker. We check how the points of their list are fulfilled, how journals and files are filled in.

Moreover, practical training is crucial in this environment, often involving at least one actual training day to enhance learning and ensure efficiency.

By the way, at this very moment, the dough maker finished making the dough. It moves further through the kitchen to the client.

If we, as managers, notice any attention points in the employee’s performance, we need to document them. We should not demotivate kitchen staff with unsubstantiated criticism. This negatively affects morale and worsens guest service. The less personal input in criticism, the better. Photos or videos usually more impartially capture challenges to pay attention to.

The observation checklist with supporting materials moves to the next stage.

Feedback

The completed SOC now serves to provide feedback to the employee. Since receiving feedback on one's work is quite personal, the manager needs to be delicate.

It is believed that a good way to provide feedback is the “sandwich method” [4]:

Similar to the structure of a sandwich, the criticism is flanked between two comments of praise.

Perhaps so, but occasionally the content of this “sandwich” is too “strong”. Even if you focus on the employee's strengths before and after the part for criticism. There might not be enough “bread.” It is also worth to consider the following [5]:

The average ratio for the highest-performing teams was 5.6 (that is, nearly six positive comments for every negative one).

However, it is not worth forcing praise out of oneself either, as it is too unnatural. So adjust the behavior to regularly notice the desired behaviors and publicly praise it. At the time when the criticism is required, there might be quite enough praise said.

Photos and videos collected in the previous stage will provide good benefits for the feedback since these are facts, not opinions. They can be relied upon in discussions.

It is crucial to listen to the employee's view. Every manager should remember that any of the existing production systems are far from perfect. Instead of routinely scolding employees for carelessness, it is necessary to focus on the best service to clients.

If improving or even creating new working conditions, equipment, or standards can improve company service, this should be done. By the way, Alexander Kasyanov became the Standards Director at “Dodo Pizza” because of his ability to look at labor organization critically.

One more thing. If the feedback concerns the personal qualities of the employee, it should be given privately.

Follow-up

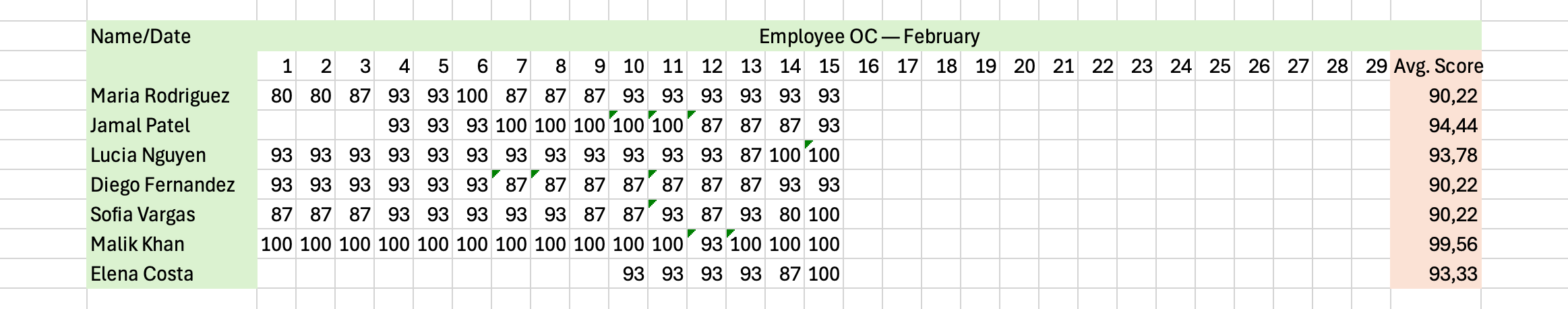

The observation checklist is the digitized result of an employee's work during a shift. The final number is important for assessing trends and comparing results from one inspection to another.

As managers, we will discuss the final score in the SOC with the employee and ensure they agree with the result. If there are disagreements, we need to argue our perspective. At the end, we discuss possible actions. It may be training, technology-based training and development programme to ensure the improvement of the required skills. It may be a task to eliminate a certain problem. The manager needs to choose what will benefit the employee's performance most.

The completed observation checklist contains the result, which is then divided by the total number of check items and multiplied by 100%. For example, our dough maker meets 14 out of 15 points, his appearance was lacking, so his result is 93%. The resulting compliance percentage is entered into the general document for kitchen staff.

Thus, each employee receives a balanced assessment of their work against the existing set of standards. The observation checklist may change over time. Despite this, we still have the opportunity to correlate his current activities in the restaurant with what was before.

Conclusion

While this material on observation checklist turned out to be quite extensive, we only considered the structure of the sheet and got acquainted with its direct application. After the assessment and control are carried out, processes begin to work, the description of which should be made into a separate material.

In short, let's recall the main points of the article. The observation checklist is necessary to help managers improve the efficiency of organization at all levels.

At “Dodo Pizza,” the observation checklist exists for four levels of the company's hierarchy: territory manager, restaurant manager, shift manager, and employees. There is also a separate SOC for shift handover control.

By the way, the entire structure of the SOCs is a tree of checklists. There is a separate post about them in the blog. Today, we have a great example of such a tool.

A detailed description of the observation checklist is good, but implementing it is much more difficult than writing. Alexander Kasyanov can help you start with this and other standardization tools. Write to him directly: @drkasianov.

* FEFO — First Expire, First Out. A principle whereby the products closest to expiration are used first.

Was it interesting to discover how checklists are applied on scale? See the “So Business List” tag to discover how they are applied in business. If you want even more, Subscribe to the “So List” blog and discover extra about the forms lists and checklists take. You’ll be amazed at their variety!

List of Links

[1] “Frederick Winslow Taylor” from Wikipedia

[2] Sociometry 1944-05, Volume 7, Issue 2, Page 150

[3] Marshall Fishwick, Ronald Revisited: The World of Ronald McDonald

[4] “The sandwich method of criticism” from the Ionos website

[5] “The Ideal Praise-to-Criticism Ratio” from Harvard Business Review website